Our first installation was unique in Moscow that’s why it struck the eye directly. We provided our machine to the experts of the Moto magazine after the professional riders of Stunt Crew successfully tested it and shortly thereafter have purchased it for the motor school. The test drive took the place in the R1 club. Journalists were so fascinated that burned down the clutch but nevertheless they have been very positively impressed.

Despite of the first pancake was not lumpy, practice makes perfect. When building up the second motorcycle we took into account all the drawbacks of the first design as followed:

The installation exceeded all the expectations. Motor school from Kuban have bought it in one month. Here it is:

When the installation was in service we have detected some of the drawbacks which have been eliminated in the third version.

We have manufactured the third Wheelie machine upon the request of a newcomer stunter from Moscow. Unfortunately we had to increase the timescale manufacturing as it supposed to make modifications and add convenient and useful devices.

What has been done:

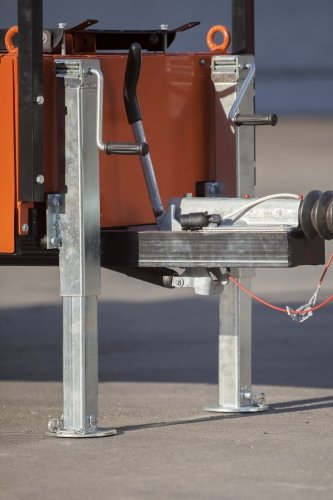

Our fourth installation is portable at two axis. According to the Wheelie machine practical experience hiring regularly a scaffold truck for the machine transportation will cost a bundle. The Wheelie machine has been hitched up to the van straightly at the plant and set out on its 1500 km way. Unfortunately we didn’t manage picture of the installation in a built-up condition, that’s why you can see just an assembled construction for transportation.

We had to change and add a great deal of stuff to make the Wheelie machine portable:

The fifth Wheelie machine is upgrade of the forth one and the second version on the base of the trailer. First of all the workmanship distinguishes this model: all the units, mechanisms, hinge, details finishing and coating is fulfilled with handcrafted perfection. And it’s out of question that this is a high-quality complete product which is beating all its counterparts across-the-board, including foreign ones.

The main emphasis is on quality but the product shows discontinuities in design also:

The aim was to improve quality overall. The aim was to improve the quality overall. Better hardware and fasteners are used. Transportation is much more comfortable due to big box under main platform with mounts for fans and spare parts.

Lighter, more compact and more comfortable:

The last version was principally the same, it is equipped with more powerful fans and weighted 20 kg less.

All subsequent wheelie machines no longer had any fundamental differences, because this design turned out to be optimal in terms of efficiency, reliability and price.

We can make a custom package for the Wheelie Machine: any color, rims, optics, tow hitch. It is also possible to significantly reduce the weight of the machine by replacing the heavy steel covering, side sheets, fan stems, front wheel springboard, and ramp with similar aluminum parts.