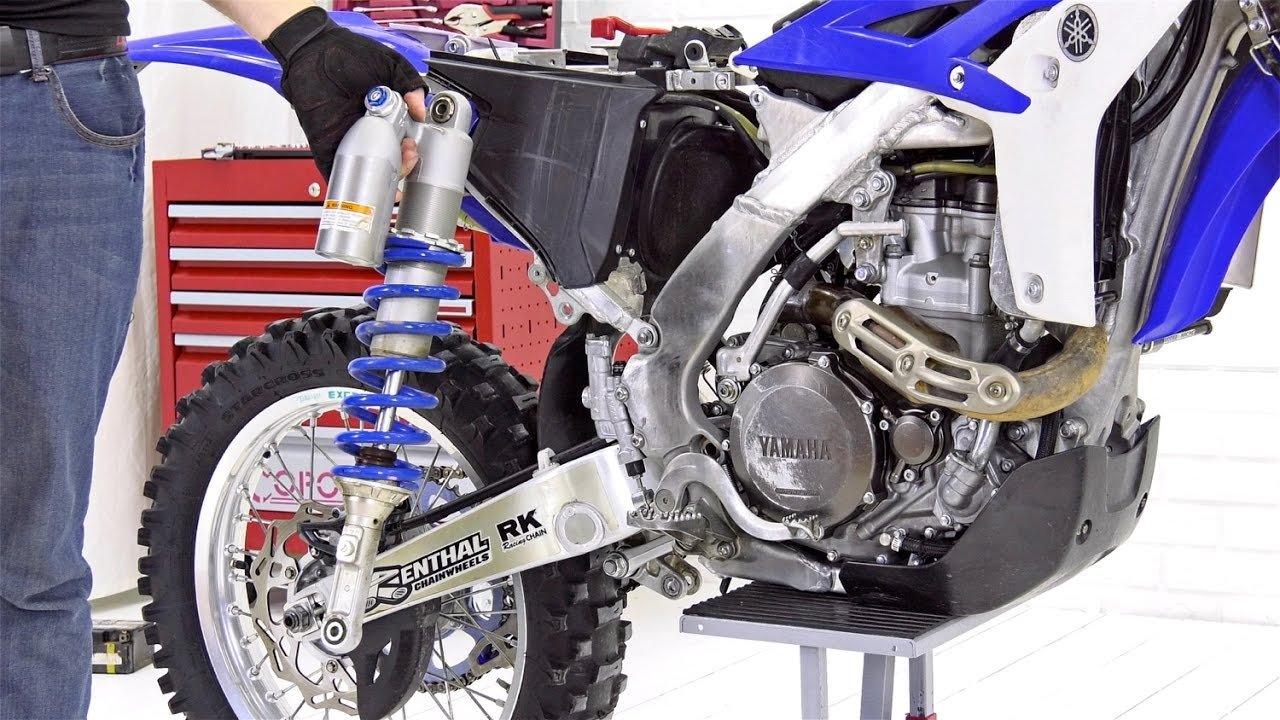

WR450F Rear Shock Rebuild

As with many motocross and enduro motorcycles, the Yamaha WR450F comes stock with a Kayaba rear shock. According to the manual, this shock is maintenance-free and must be replaced in case of malfunction. This is due to the fact that there is no valve with a nipple to control the pressure in the tank, and the pear itself will be used for 2-3 dozen punctures, so it is impossible to regularly check the pressure. If the pressure drops, firstly - when it is heated, cavitation occurs and the oil is filled with air bubbles, and secondly - the pear may leak air due to less tight adhesion to the tank body. Professional shocks are equipped with a valve and a piston instead of a pear, which guarantee tightness and allow you to repeatedly check the pressure.

The cost of the a new shock is comparable to the cost of a second-hand motorcycle , so it is cheaper to repair, despite the "non-servicing", and practice shows that it is quite realistic and works well. See below for detailed videos on how to remove and repair a shock absorber, as well as read about interesting moments that were not included in the videos.

Shock absorber leaking

If the shock is leaking, you must first check the pressure in the tank and pump it up if the pressure drops. If the pressure is normal, and the shock absorber leaks- it is necessary to change the oil seal. It may be necessary to bleed air through the compression valve.

Repair kit

Repair kits are different. The video shows the most expensive option: a sleeve with pre-installed gland, boot, and guide ring. You can buy the gland, boot and ring separately, and independently replace them in the sleeve - it will be cheaper! It is advisable to change the pear when disassembling.

Oil

It is best to use oil for the shock absorber, which has a viscosity index under 400. This oil is not sold everywhere, so most use fork 5W or 2.5W (viscosity index 100-150). The viscosity index characterizes the dependence of viscosity on temperature; the lower the value, the thicker the oil becomes when the temperature decreases, and it dilutes with an increase. In practice, the fork oil thickens in winter and the shock becomes very tough. If you do not ride in the winter, then the fork oil is ok.

Tank plug

On the 2012 WR450F there is a tank cap without a valve. Such plugs need a special needle. We replaced this plug with a plug with a valve from the WR250F 2008 - it fit perfectly and solved the problem with the needle. In fact, finding a plugwas not easy.

Rod nut

On Kayaba shock absorbers, the flaring of the nut can be cut off completely - this allows you to save the nut. But some shocks (for example, Showa), flaring holds the adjustment mechanism for the rebound, so it can not be ground completely. As a rule, all fix the nut on the high-strength thread lock. It is important to degrease the thread and allow the retainer to dry before reassembling. The most reliable option is welding.

Rear shock assembly

There are many videos on the internet of a wet shock absorber assembly: it is filled with oil, the tank and stem are installed, and the oil is poured. The popularity of the method is incomprehensible, because a lot of oil is consumed, it is very difficult to push the stem plug and install the retaining ring, plus often there is air in it. The only plus is that you don’t have to unscrew the compression valve, but it’s not hard to do. We did a dry assembly, which is simple, reliable, and requires minimal oil.

Bleeding of air

After pumping the shock absorber there should be no air - it can be heard when the rod is moving. If the air remains, it can be released by loosening the compression valve plug when the shock is in a vertical state. The pressure in the tank will drop, so it must be pumped up.

Air or nitrogen

The tank must be pumped with nitrogen. Nitrogen has more molecules, so it is better retained. Nitrogen has less thermal expansion, so pressure is maintained at different temperatures. Nitrogen does not heat as much under pressure. In reality, 75% of nitrogen is in the air - so there is no tangible difference. Installation for injection of nitrogen under high pressure is very difficult to find. The experience of many motorcyclists shows that air also works fine. It is necessary to regularly check the pressure, and there will be no problems.

It is recommended to service the bearing on the removed shock absorber. Strictly speaking, the shock absorber bearing is serviced along with the progression arms, but there is not always time and desire to remove the shock absorber for this.

Hopefully this information is helpful. Criticism and comments - email or in the comments on Youtube!