Motorcycle Plastic Repair

To repair plastic is extremely topical for all riders who train actively. Not only fairings, fenders and shrouds on a motorcycle are made of plastic, but also elements of protection and equipment. Classic repair with zip-ties are not suitable for all parts and not as reliable as welding. The weld is not inferior in strength to a monolithic joint.

In this video Gena Zyrin repairs without special equipment the cracked radiator shroud of his motocross bike, the helmet visor and the skid plate Moose Racing, which are made from polyethylene. This is especially true for training equipment. Even though the plastic of a cross or enduro motorcycle is not pricey, it breaks frequently with regular training. To buy a new part every time when it breaks is expensive, and sometimes it’s not easy to find it in stock. Repairing will save not only your money, but also your time.

You can repair plastic at home with a heat gun. The main thing is to choose the right donor and adequate temperature mode.

The direction, distance and area of the heat flow, which are selected experimentally, are also important. Certainly, to use a professional tool and special rods to weld plastic is easier, but without special equipment you can also do it equally well.

How to choose a donor

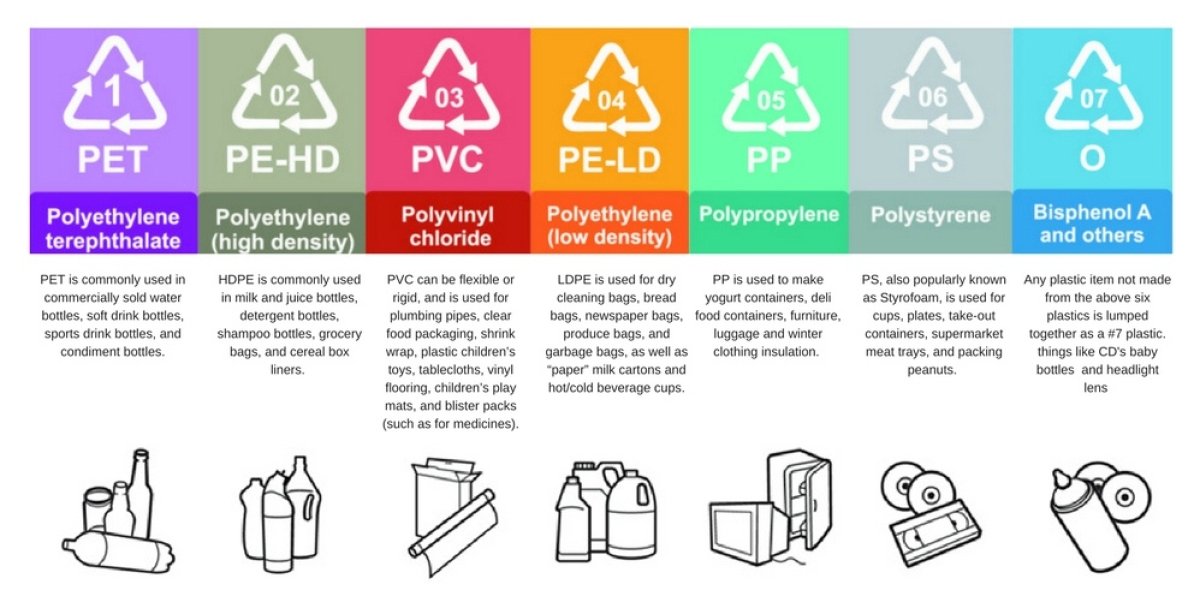

It is the best practice to use a similar part as a donor, which diffuses well and has the same color. If there is no such detail, then it is possible to choose the donor from household items by marks, which are usually made everywhere.

Below there is a table with the types of plastic and the products in which they are used.

Professionals can weld plastic of various types and combinations, but without experience it is very difficult to do.

Before he was shooting that video, Gena welded the skid plate with plastic bottle caps - it looked rather ugly (it was necessary to heat the donor and the skid plate body to ensure good diffusion), but reliable, he even managed to test it. That is why we decided to make a full video and specially for it we broke off the skid plate again to weld it in the video. Household donors can be used effectively - verified!

Of course, special plastic rods are much more convenient to use, but they are not sold everywhere.

What temperature mode

The melting point of all types of plastic is known, but it is useless if you weld the plastic with a heat gun. The temperature setting on the heat gun does not correspond to the temperature of the air flow at the outlet with different nozzles, and especially the temperature of the flow at a distance. You have to find the temperature mode on each specific heat gun with a specific nozzle experimentally. In our video, Gena announced the temperature on a Dexter heat gun for polyethylene and polypropylene.

How to weld

The flows direction, the distance to the seam and the position of the solder depend on the type of plastic, thickness of body and are selected experimentally on test samples. In the welding process, we made the following conclusions:

- If the thickness of the solder and body are the same as on the plastic from mx or enduro bike, then the flow is directed along the bisector of the angle between the solder and the body, i.e. they are heated and melted the same way. On motocross bikes plastic is made of soft polypropylene - it is the easiest to weld.

- If you repair fragile and hard ABS plastic on road motorcycles - it’s harder to weld because it is necessary to heat up more. That is why the body is deformed during welding.

- If the thickness of the body is much greater than the thickness of the solder, such as a skid plate, then the flow is directed more toward the body than at the solder so that it does not melt while the body is warming up. In that case, the solder is recessed into the molten body under slight pressure.

- If the body is very thin, such as the visor of a helmet made of polycarbonate, it is easier to weld without a narrow nozzle, so as not to burn the body. It also makes sense to put a wet rag under the body, which will reduce the deformation during welding.

In the video Gena was repairing plastic and a visor for the first time in his life - it turned out satisfactorily: reliably, but not beautiful enough. If beauty doesn’t really matter, anyone can handle repairing plastic on their own and at the first time!